|

Research Ideas and Outcomes : PhD Project Plan

|

|

Corresponding author: Sriswaroop Dasari (sriswaroopd@gmail.com)

Received: 04 Oct 2016 | Published: 12 Oct 2016

© 2016 Sriswaroop Dasari.

This is an open access article distributed under the terms of the Creative Commons Attribution License (CC BY 4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Citation: Dasari S (2016) Studying the effect of Ruthenium on High Temperature Mechanical Properties of Nickel Based Superalloys and Determining the Universal Behavior of Ruthenium at Atomic Scale with respect to alloying elements, Stress and Temperature. Research Ideas and Outcomes 2: e10714. doi: 10.3897/rio.2.e10714

|

|

Abstract

Any property of a material is a function of its microstructure and microstructure is a function of material composition. So, to maximize the desired properties of a material, one has to understand the evolution of microstructure which in turn is nothing but the reflection of the role of alloying elements. Research has not been done to understand the universal behavior of a certain base/alloying element. Let’s take the example of Cl- ion in HCl, we all know that in general, chloride ion can only be replaced by Fluoride or oxygen ion and that no other ion can replace it. But when you consider a metal like Ni, Co, Cr, Fe etc. there is no establishment that it behaves only in a certain way. Though I concord to the fact that discovery of universal behavior of Ni is lot complex than chloride ion, I think that future research should be focused in this direction also. Superalloys are the candidate materials required to improve thermal efficiency of a gas turbine by allowing higher turbine inlet gas temperatures. Gas turbines are the heart of local power systems, next generation jet engines and high performance space rockets. Recent research in superalloys showed that addition of some alloying elements in minor quantities can result in drastic change in properties. Such an alloying element is Ruthenium (Ru). Addition of Ruthenium to superalloys has shown improvement in mechanical properties by an order of magnitude. However reasons for such improvement are not known yet. Hence, there is a need to identify its role and discover the universal behavior of ruthenium to utilize it efficiently. In this proposal, we study materials with different compositions that are derived based on one ruthenium containing superalloy, and different thermomechanical history. Based on the evolution of microstructures and results of mechanical testing, we plan to determine the exact role of Ruthenium and prediction of its behavior with respect to other elements in the material such as Ni, Cr, Co, Mo, W etc. and stress and temperature. This helps us to determine the right quantity of ruthenium required for a given composition and operating conditions.

Keywords

Ruthenium, superalloy, mechanical properties, thermomechanical processing, creep, proposal

Significance

The present researchers in material science design a suitable material to the given conditions based on the past knowledge and experiences with different alloys studied till date. It has been mostly trial and error design. This proposal suggests a plan to understand the universal behavior of every chemical element so that we shall be able to identify the limit of such element in the given application. Such study should not be limited to ruthenium but has to be extended to every chemical element. Ruthenium enhances the mechanical properties by quantities in a way that they had to be classified as fourth generation superalloys (

Objectives

1. Identification of the role of Ruthenium as an alloying element in the modification of microstructure and mechanical properties of superalloys.

2. Extension of the study to different compositions so as to understand the way ruthenium behaves when certain chemical elements or conditions are imposed.

3. Feasibility of the study of universal behavior of a certain chemical element.

4. Extension of the same studies to all chemical elements by establishing a standard that has to be followed to perform such research.

5. Feasibility of extension of such research not only to various fields in materials science but also to different branches of science itself.

Overview of Relevant Literature

The highly beneficial qualities of ruthenium to superalloys has been discovered very recently. Since then, many researchers have tried to understand the role of ruthenium but were able to make intermediary conclusions that are directly understood from their experiments. Atomic scale conduct of Ru has not been completely understood. The current understanding of ruthenium as per available literature till now goes as follows:

- Ruthenium helps in producing a microstructure with smaller and more regular γ’ and denser dislocation structure at γ/ γ’ interface (

Pyczak et al. 2009 ,Tan et al. 2011 ). - Ruthenium suppresses or at least doesn’t affect the tendency of the alloy to form topologically closed pack phases (TCP), (

Sato et al. 2006 ,Tan et al. 2011 ,Tsuno et al. 2008 ) - While it preferentially partitions to γ, it increases the tendency of the elements Re, W, Mo, Cr, Co to partition to γ’, the so called reverse partitioning (

Yokokawa et al. 2004 ). - It promotes square dislocation networks and change of γ/γ’ misfit which is beneficial to the mechanical properties of superalloys (

Tan et al. 2011 ).

Experimental Plan and Procedures

a. Design of ingots

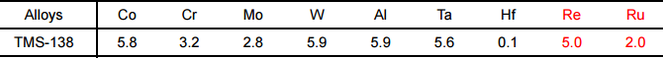

Consider the Ni-based superalloy TMS 138 which has the composition shown in Fig.

Design of alloy compositions containing ruthenium. *RHEA – High entropy alloy with Ruthenium, *RCA – Conventional alloy with Ruthenium

|

Sl. No. |

Alloy |

Referred to as |

|

1. |

50Ni – 50Ru |

(RHEA1) |

|

2. |

33.34Ni – 33.33Co – 33.33Ru |

(RHEA2) |

|

3. |

25Ni – 25Co – 25Cr – 25Ru |

(RHEA3) |

|

4. |

20Ni – 20Co – 20Cr – 20Al – 20Ru |

(RHEA4) |

|

5. |

16.67Ni – 16.66Co – 16.67Cr – 16.66Al – 16.67Ta – 16.67Ru |

(RHEA5) |

|

6. |

14.28Ni – 14.28Co – 14.28Cr – 14.28Al – 14.28Ta – 14.28Mo - 14.28Ru |

(RHEA6) |

|

7. |

12.5Ni – 12.5Co – 12.5Cr – 12.5Al – 12.5Ta – 12.5Mo – 12.5Re – 12.5Ru |

(RHEA7) |

|

8. |

11.11Ni – 11.11Co – 11.11Cr – 11.11Al – 11.11Ta – 11.11Mo – 11.11Re – 11.11W –11.11Ru |

(RHEA8) |

|

9. |

10Ni – 10Co – 10Cr – 10Al – 10Ta – 10Mo – 10Re – 10W – 10Hf – 10Ru |

(RHEA9) |

|

10. |

97Ni – 3Ru |

(RCA1) |

|

11. |

88.88Ni – 8.31Co – 2.77Ru |

(RCA2) |

|

12. |

85.12Ni – 7.98Co – 4.25Cr – 2.66Ru |

(RCA3) |

|

13. |

80.8Ni – 7.56Co – 4Cr – 7.56Al – 2.52Ru |

(RCA4) |

|

14. |

75.52Ni – 7.05Co – 3.77Cr – 7.05Al – 6.6Ta – 2.36Ru |

(RCA5) |

|

15. |

72.96Ni – 6.84Co – 3.64Cr – 6.84Al – 6.38Ta – 3.19Mo - 2.28Ru |

(CAR6) |

|

16. |

69.12Ni – 6.48Co – 3.02Cr – 6.48Al – 6.04Ta – 3.02Mo – 5.4Re – 2.16Ru |

(RCA7) |

|

17. |

65Ni – 6.09Co – 3.24Cr – 6.09Al – 5.68Ta – 2.84Mo – 5.07Re – 6.09W – 2.03Ru |

(RCA8) |

|

18. |

63.7Ni – 5.8Co – 3.2Cr – 5.9Al – 5.6Ta – 2.8Mo – 5Re – 5.9W – 0.1Hf – 2Ru |

(TMS 138) |

Design of alloy compositions that does not contain ruthenium. *HEAX0 – High entropy alloy with zero ruthenium, *CAX0 – Conventional alloy with zero ruthenium

|

Sl. No. |

Alloy |

Referred to as |

|

19. |

100Ni |

(HEA10) |

|

20. |

50Ni – 50Co |

(HEA20) |

|

21. |

33.34Ni – 33.33Co – 33.33Cr |

(HEA30) |

|

22. |

25Ni – 25Co – 25Cr – 25Al |

(HEA40) |

|

23. |

20Ni – 20Co – 20Cr – 20Al – 20Ta |

(HEA50) |

|

24. |

16.67Ni – 16.66Co – 16.67Cr – 16.66Al – 16.67Ta – 16.66Mo |

(HEA60) |

|

25. |

14.28Ni – 14.28Co – 14.28Cr – 14.28Al – 14.28Ta – 14.28Mo – 14.28Re |

(HEA70) |

|

26. |

12.5Ni – 12.5Co – 12.5Cr – 12.5Al – 12.5Ta – 12.5Mo – 12.5Re – 12.5W |

(HEA80) |

|

27. |

11.11Ni – 11.11Co – 11.11Cr – 11.11Al – 11.11Ta – 11.11Mo – 11.11Re – 11.11W – 11.11Hf |

(HEA90) |

|

28. |

97Ni – 3Co |

(CA10) |

|

29. |

88.88Ni – 8.31Co – 2.77Cr |

(CA20) |

|

30. |

85.12Ni – 7.98Co – 4.25Cr – 2.66Al |

(CA30) |

|

31. |

80.8Ni – 7.56Co – 4Cr – 7.56Al – 2.52Ta |

(CA40) |

|

32. |

75.52Ni – 7.05Co – 3.77Cr – 7.05Al – 6.6Ta – 2.36Mo |

(CA50) |

|

33. |

72.96Ni – 6.84Co – 3.64Cr – 6.84Al – 6.38Ta – 3.19Mo - 2.28Re |

(CA60) |

|

34. |

69.12Ni – 6.48Co – 3.02Cr – 6.48Al – 6.04Ta – 3.02Mo – 5.4Re – 2.16W |

(CA70) |

|

35. |

66Ni – 6.29Co – 3.44Cr – 6.29Al – 5.78Ta – 2.34Mo – 5.17Re – 6.19W – 0.3Hf |

(CA80) |

For comparison, all the 18 ingots in Table

b. Thermomechanical processing

Now thermomechanical processing is performed on all samples (five from each ingot) to different strains/temperatures/times. All the samples must be first solution treated (ST) but the temperature will vary with composition. After solution treatment, samples undergo different amount of cold working, 0%, 20%, 40%. It is followed by aging treatments to several tens of degrees below ST temperature. Dual aging and grain boundary engineering can also be performed depending on the performance of the samples with temperature. A sample heat treatment schemes on any of the ingots may look as follows:

- ST to 1150 C/12hrs + air quench

- Cold working of sample using a rolling mill where its thickness is decreased by 20%

- Aging to 870 C/24hrs + air quench

c. Mechanical Testing

Mechanical testing of the samples will be carried out using hardness tester and creep testing equipment. Hardness tests can be done by using Rockwell microhardness tester. Creep tests have to be performed over a range of temperatures and stresses for at least 500hrs to assess the role of ruthenium. Possible creep testing conditions for many ingots can be as follows:

- 850 C/490MPa

- 950 C/275MPa

- 950 C/350MPa

- 1000 C/175MPa

- 1100 C/140MPa

All the creep tests will be performed in only one crystallographic direction, say <001> so that we shall be observing the mechanical behavior in one direction in all samples.

d. Microstructural Characterization and Electron Dispersive Spectrometry

As the microstructural evolution has to be studied, microstructures have to be taken before and after every single treatment on the sample. Microstructures of all samples must be recorded using a Scanning electron microscope (SEM). Every microstructure have to be studied in terms of grain size, distribution and percentage of precipitates. Focus should be more on comparison between the ingots that have similar compositions but with and without ruthenium. Current technology allows us to perform in-situ SEM during heat treating and it will be utilized wherever necessary and appropriate. Samples from creep tests have to be electrochemically polished and observed under a Transmission electron microscope to study the γ’ and precipitate morphology in the sample. Electron dispersive spectrometry (EDS) will be performed on all samples except on HEA10 to study the precipitates and partitioning of alloying elements to γ, γ’ and topologically closed pack phases (TCP). As the alloy does not contain elements with atomic number less than six, EDS is a non-destructive, quick and effective technique for composition analysis.

Results and Statistical Analysis of Results

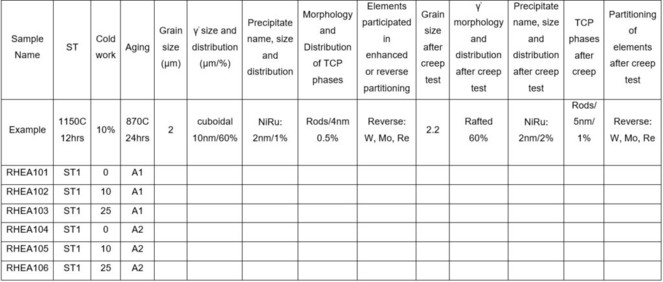

Every feature of microstructure and every property of the material speaks about the role of the alloying elements. But due to time constraint, all the features of microstructures but only certain important properties of the material, hardness and creep rupture life will be determined under this proposal. The mechanical properties of six samples taken from RHEA1 ingot that have different thermomechanical processing history can be as shown in Table

Hardness and creep rupture life of six samples from RHEA1 ingot. *RHEA10X – Sample from RHEA1 ingot with a thermomechanical history represented by X, **ST1 – Solution Treatment temperature for the specific alloy, ***A1, A2 – Aging treatments specific to that alloy

|

Sample Name |

ST |

Cold work |

Aging |

Hardness (hν) |

Time to 1% Creep Strain |

|

|

950C/ 350MPa |

1100C/ 140MPa |

|||||

|

RHEA101* |

ST1** |

0 |

A1*** |

|||

|

RHEA102 |

ST1 |

20 |

A1 |

|||

|

RHEA103 |

ST1 |

40 |

A1 |

|||

|

RHEA104 |

ST1 |

0 |

A2 |

|||

|

RHEA105 |

ST1 |

20 |

A2 |

|||

|

RHEA106 |

ST1 |

40 |

A2 |

|||

All features of the microstructures from the six samples taken before and after creep tests

Statistical analysis of the data obtained in Table

Discussion

From the observations, metals may be ranked in an ascending order similar to an electrochemical series. This series tells how a metallic element behaves when a certain element/group of elements are present in the alloy. I suppose it is impossible to anticipate the role of ruthenium in the alloy without performing the actual experiments. However, this proposal gives an estimate of the quality and quantity of work and time needed for such study and the appropriate methods that are to be followed to achieve a good understanding of ruthenium. The results act as a database to determine the right quantity of ruthenium to a given composition and a given set of operating conditions. The proposal also acts as a guide for experimentation to understand the universal behavior of other alloying elements like Cr, Co, Hf, Mo, W etc.

Possible Extensions

The research of understanding the universal behavior of Ruthenium can be further extended to every other alloying element Ni, Cr, Co, Hf, Mo etc. so that there will be a complete understanding of what a certain element can do with its partner elements and imposed conditions. This proposal will act as the first step towards designing ideal compositions for a specific application.

Timeline

To reduce the time for experimentation, this work will be done by collaborating with one more researcher belonging to a different research organization. The work at the other institute consists of creep testing of half the samples i.e. 210 samples. As this proposal requires heavy logical thinking, understanding and knowledge of the subject rather than just experimentation, it requires four graduate students and a period of six years. The timeline for the proposal follows Table

Timeline for the proposal

| Task | Time required |

|

Preparation of 34 different ingots with varying compositions |

1 year |

| Sample cutting for various tests | 8 months |

| Thermomechanical processing |

6 months |

| Mechanical testing (assuming at least 2 creep testers) | 3 years |

| Microstructural Characterization |

6 months |

| Interpretation and co-relation of results | 4 months |

Acknowledgements

I am thankful to all of my teachers especially to Dr. John. J. Mecholsky, University of Florida, USA for the guidance on writing a research proposal.

References

-

Superalloys.35-43pp. URL: https://doi.org/10.7449/2004/superalloys_2004_35_43 DOI: 10.7449/2004/superalloys_2004_35_43

-

Fourth generation nickel base single crystal superalloy TMS-138/138A.1-6pp. URL: http://sakimori.nims.go.jp/catalog/TMS-138-A.pdf

-

Influence of lattice misfit on the internal stress and strain states before and after creep investigated in nickel-base superalloys containing rhenium and ruthenium.Materials Science and Engineering: A510-511:295‑300. DOI: 10.1016/j.msea.2008.08.052

-

The effects of ruthenium on the phase stability of fourth generation Ni-base single crystal superalloys.Scripta Materialia54(9):1679‑1684. DOI: 10.1016/j.scriptamat.2006.01.003

-

Effect of ruthenium on high-temperature creep rupture life of a single crystal nickel-based superalloy.Materials Science and Engineering: A528:8381‑8388. DOI: 10.1016/j.msea.2011.07.075

-

Effect of Ruthenium on Creep Strength of Ni-Base Single-Crystal Superalloys at 750 °C and 750 MPa.Metallurgical and Materials Transactions A40(2):269‑272. DOI: 10.1007/s11661-008-9744-6

-

Superalloys.859-866pp. URL: https://doi.org/10.7449/2004/superalloys_2004_859_866 DOI: 10.7449/2004/superalloys_2004_859_866